How to get rid of plastic and why is it hard to do it

It’s no secret that plastic is toxic both for people and the environment.

Even more, only a very small percentage of the world's plastic is recycled. And yet, the global demand for plastics keeps growing.

So, why is it so difficult to get rid of it?

Anna-Liisa Palatu, Woola's CEO, joined a panel discussion on the issue with Lise Nicolas, co-founder of Mr. & Mrs. Recyclage and Samuel Jouzel, CEO and co-founder of Binocle, to attempt to provide an answer to this question.

Panel discussion at Woola Experience Event in Paris. From left: panel moderator Antoine Leyh, Lise Nicolas, Samuel Jouzel and Anna-Liisa Palatu.

Plastic is still used on a large scale...

How can we explain its wide use when we are well aware of its damaging effects?

"It's cheap, and it's not necessarily a bad material. The problem is that it's not used well: it's used once and then thrown away because recycling it costs more than making it."

— Anna-Liisa Palatu, CEO and co-founder of Woola

Lise agrees that the problem lies in how the material is used, not in the material itself, and sheds light on the key characteristics of plastic.

"I think that we really need to understand plastic and its detrimental effects so that we don't polarize the debate," said Lise.

"It's a very interesting material: it’s light and sturdy. If we compare glass and plastic bottles, for example, we will have to produce much more glass than plastic to create one bottle, so we will have to extract more material,” she continued

“The real problem lies in our use of plastic: we have to change our consumption patterns to avoid disposable plastic as much as possible. Plus its production consumes a lot of energy: it's not priced right when you compare the energy cost of plastic consumption."

— Lise Nicolas, co-founder of Mr. & Mrs. Recyclage

Samuel Jouzel summed it up nicely, saying "We need to start using it in a smart way right away because it's a limited resource."

...yet it is difficult to create a circular economy for plastics.

In addition to the linear use issue of plastic, recycling it is also challenging. It may surprise you, but from a technological point of view, 100% of plastic can be recycled.

However, the reality of plastic circularity is far off from our aspirations. Even in the EU, which is considered a world leader in plastics circularity, only about one-third of plastic packaging is actually recycled.

In 2020, each person living in the EU generated 34.6 kg of plastic packaging waste on average, out of which 13.0 kg was recycled. (Source)

"In terms of recycling, there is a big difference between theory and practice," said Lise.

"If you look at single-use packaging everything is theoretically recyclable, but it's a process that requires a lot of steps, companies, and interactions put together and if there is a missing link, the recycling loop can't be closed. There is no such thing as a magic plastic recycling process."

— Lise Nicolas, co-founder of Mr. & Mrs. Recyclage

Another issue involves the design of plastic products, which are not always designed to be recycled.

"If we were more careful about its design, we could recycle more plastics," Samuel added. "We shouldn't combine plastic with other materials in a way that makes them harder to recycle — like how bubble plastic wrap is often attached to the paper envelope itself, for example. So we need to think about the eco-design of plastic products as well."

P.S. That's the main reason why the wool layer of Wool Envelopes is not attached to the paper exterior — that way, both materials are easy to recycle.

Alternatives exist, but they are not all equal.

When it comes to alternatives to plastic, we must think about both about what kind of materials are feasible and how we use them.

Lise shared: "In terms of ways of use: it is essential to design for reuse or create deposit-based circular systems. When it comes to materials, we have to move towards recycled or biosourced materials. If materials are biodegradable and compostable, we also have to make sure the infrastructure is there to manage end-of-life."

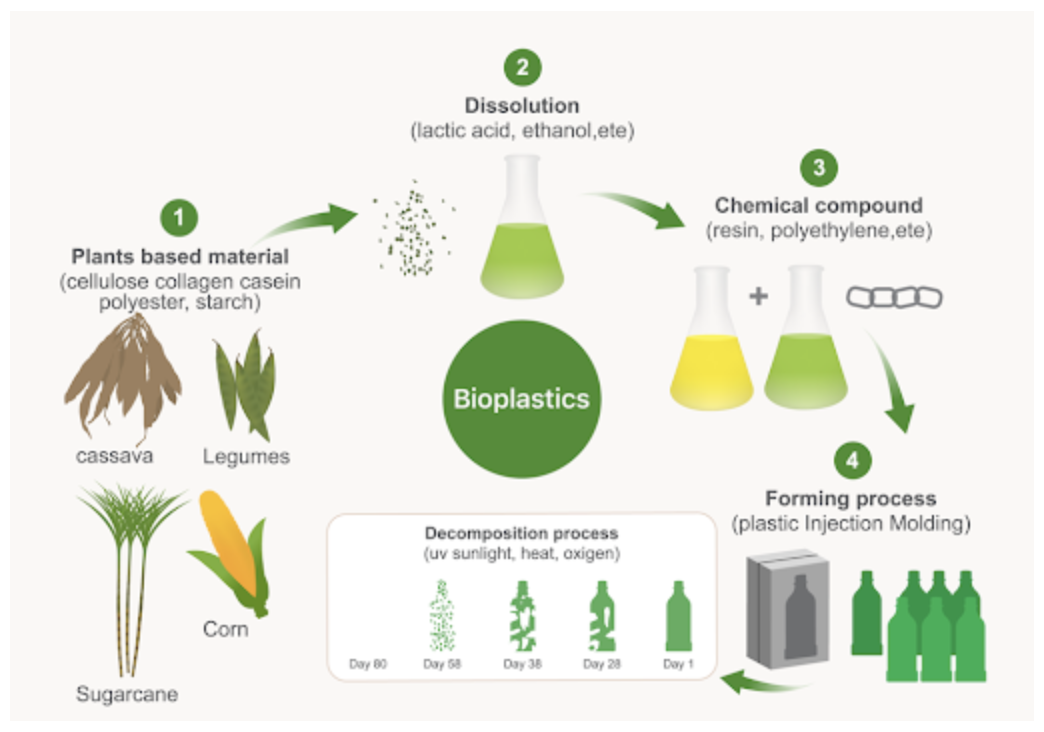

How bioplastics are made

Materials produced from renewable biomass sources are gaining steam in the packaging world, as demand for compostable packaging grows.

But to be competitive, these alternatives must be light, sustainable and easy to use. Are plant-based alternatives such as bioplastics a realistic solution? Is this a miracle solution for the future of packaging?

"The main difference between plastics and bioplastics is that bioplastics are made from plants and not from fossil fuels. So the demand for fossil fuels is lowered, but most bioplastics are not compostable at home, only through an industrial facility — and these are not easily accesible for the public. So, it's better but it's still a temporary solution."

— Anna-Liisa Palatu, CEO and co-founder of Woola

And Lise added: "Biodegradable bioplastics are the ultimate solution in theory: the material decomposes and is absorbed by nature when it is no longer needed. But the challenge is in who manages it at the end of its lifecycle, in practice.”

There’s also the topic of resources that go into making bioplastics. “Bioplastics are not made of waste products,” Lise said. “But from plants like corn or sugarcane that need to be produced for this purpose. So it does not necessarilty mean that no fossil fuels were burned for making them — for example, oil is typically required to run a tractor! Even more, GMOs are often used to increase production.”

“In theory, biodegradable bioplastics can be a good solution for disposable packaging. In practice, it's a big no because it raises many different issues and challenges that need to be solved before we can turn to this solution without concerns."

— Lise Nicolas, co-founder of Mr. & Mrs. Recyclage

"It was hard to figure out how to 'fix' the packaging industry," Anna-Liisa added. “It has taken a long time to understand the cause of climate change, but it’s clear the main cause is burning fossil fuels, especially when used to make plastic. So when we created Woola, we had two goals: get rid of fossil fuels and single use mentality.”

This is something more and more companies are moving towards.

"I decided to replace plastic with wool packaging after an environmentally conscious realization," Samuel added. "We removed all the plastic that was useless.”

Even more, Binocle re-evaluated their ecommerce packaging: “As our business relies a lot on ecommerce, we had the the opportunity to use Woola envelopes,” said Samuel.

“They’re made of natural cardboard which can be recycled with paper and cardboard, and the wool part which is really interesting, because it's made of something that would otherwise go to waste, and it can easily be reused. Plus, there are many fun ways to give the wool inlay a second life: washcloths, pet toys..."

Lise concluded: "When it comes to single-use packaging, 60% of the environmental impact happens during production. So using a waste material to create products is a huge strength of Woola, as it prevents the impact associated with resource extraction in the first place.

The ideal alternative to plastic using waste to create new materials, just like Woola does with sheep wool."

Then, how can we change the world?

As a last question, the panelists were asked how we can change the world.

Anna-Liisa said the use of fossil fuels and oil must be stopped. As for Lise, she said change must happen in the consumption patterns: to consider the resource at its true value for use, reuse and recycling.

According to Samuel, change must come from raising awareness regarding our daily carbon impact and the fact that there was a life before plastic, so there has to also be a life after plastic.