Testing Woola’s sustainable durable packaging

P.S: To turn on subtitles on the videos, click on the button next to ⚙️ icon on the bottom of the video.

Wool is a naturally high-tech material: it has high thermal resistance, elasticity and the ability to absorb moisture.

At the same time, as wool is a novel packaging material, its protective properties are not well known (yet!). So, we set out to test and measure how durable Woola packaging truly is, from its resistance to shocks and temperature extremes to water repellency.

Read on or jump to the test that interests you:

Test 1: Is Woola packaging shockproof?

There’s no official international standard for how well-protected postal packaging has to be. However, several courier companies have shared with us that postal packages have to endure a fall from one metre height.

As Woola packaging is designed to replace plastic bubble wrap in protecting fragile goods when they’re shipped, this test is the most crucial one for us.

To test how shockproof our packaging is, we created a drop test with the Wool Envelope and a couple of different fragile items: a small bottle of a ginger shot, a jar of toothpaste tablets, a Nokia 5110 and a book.

Even after being dropped from a height of one metre, the items remained completely intact, thanks to the shock-absorbing properties of the Wool Envelope.

We also wanted to see what happens if something drops on the package, as this is quite likely to happen to parcels during shipping. To test this, we kept a cosmetics jar in the Wool Envelope and dropped different items on it from one metre height.

Once again, the product inside the Wool Envelope was unharmed. See both shock-resistance tests in action in the video above.

Test 2: Are Wool Envelopes waterproof?

The exterior of a wool fibre is hydrophobic, which means it repels water while the interior of the fibre is hygroscopic, attracting water (source). As a result, wool fibres absorb water well — as much as one-third of its own weight — while the exterior surface of the fibres remains dry.

This makes wool fabrics excellent for repelling moisture. In the context of wool packaging, this means that the material offers protection against water – to an extent.

While postal packages only get wet when something really goes wrong on their journey, protecting the products inside becomes very important on those rare occasions.

As many goods have a cardboard box as the product packaging, we imitated a realistic use case by placing a smaller Wool Envelope inside a larger one and then pouring water over it.

The result? The smaller envelope remained completely dry, and the wool inlay of the larger was also dry to touch.

We then tried pouring even more water over the envelope to simulate a very rainy day, but the result was the same. See it in action:

While it's important to note that wool is not completely waterproof, our internal testing showed that the Wool Envelope floats when placed in a bigger body of water, due to the air trapped in the paper envelope and in the wool inlay.

It didn’t sink even when we put several kilograms of extra weight on top of it. The Wool Envelope sank only when forced underwater with more weight. In such a case, its water repellency depends mostly on how well the paper envelope is sealed.

If you missed it, watch the waterproof test video above.

Test 3: Does wool protect from temperature extremes?

Another wonderful characteristic of wool is its high thermal resistance, which makes it an excellent insulator.

Thermal insulation packaging is a whole category of its own, with companies like Woolcool and Puffin Packaging creating solutions with wool for the food and pharma industries.

While Woola packaging does not offer full insulation, the wool layer does provide some protection against temperature extremes during shipping.

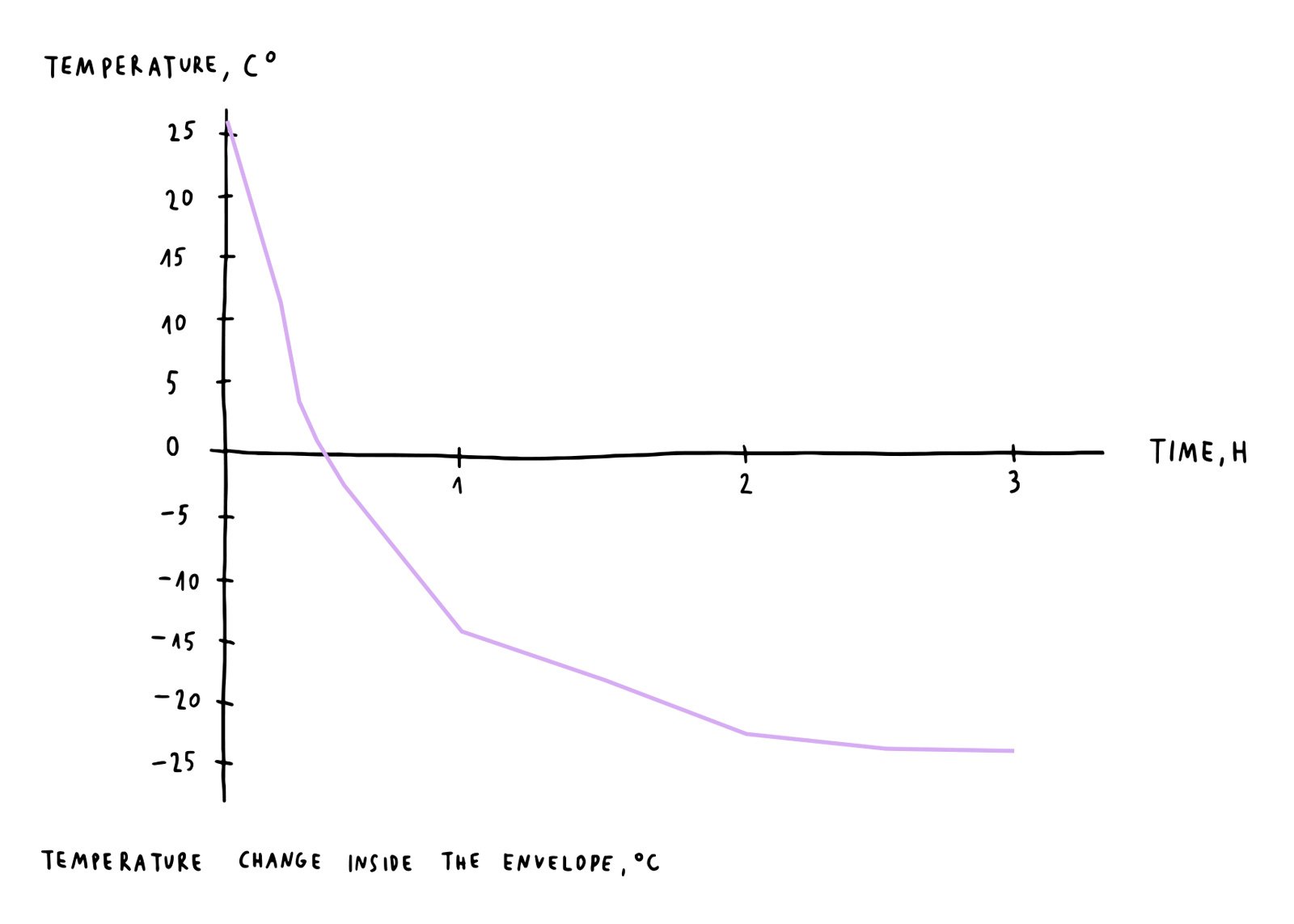

To test resistance to freezing temperatures, we put a temperature sensor inside a carton box, packed it in a Wool Envelope and placed it in a freezer at -18°C.

The starting temperature was 25.2°C and it took a little over half an hour (31 minutes to be precise) for the sensor to indicate a temperature below freezing.

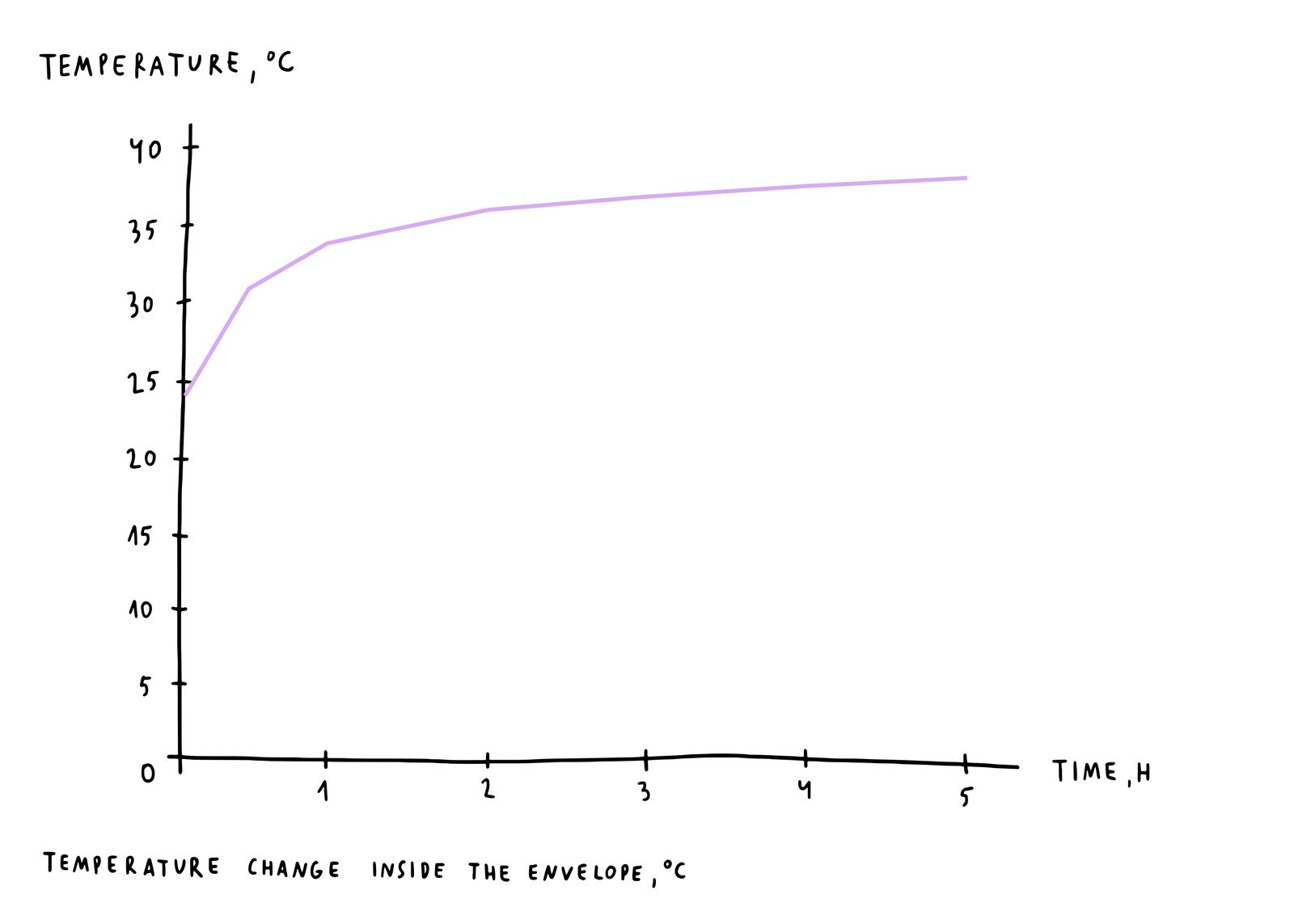

Next, we trialled resistance to high temperatures – after all, summer heat waves are the new norm in Europe. We one again placed the sensor inside a carton box that was inside a Wool Envelope and then placed it in an oven at 38°C.

The starting temperature was 24.2°C and it took about half an hour for the sensor to indicate a temperature above 30°C. From there, the temperature rose a bit more gradually, reaching 34°C in an hour and 37°C in three and a half hours. After that, it took one and a half hours to reach the full 38°C.

While the insulation of Wool Envelopes is temporary, it does offer some protection. This makes Woola packaging a good choice for shipping products that are sensitive to temperature extremes, such as cosmetics.

In case you missed it, you can find the video overview about how wool protects against temperature extremes (and fire) above.

BONUS: is Woola packaging fireproof?

When it comes to fire resistance, there’s no natural fibre that compares to wool. In fact, even the majority of synthetic fibres don’t come close.

Wool ignites at around 570-600°C (source), which is more than double the ignition temperature of cotton and higher than most synthetic fibres. Even more, wool has a lower rate of flame spread, heat release, heat of combustion, and it does not melt or drip. Finally, it forms a char that is insulating and self-extinguishing (source).

So, when we put a Wool Envelope to the fire resistance test, we had high hopes – and wool did not let us down. We tried igniting the wool inlay of Woola envelopes with a torch and found that it didn’t really catch fire. It burned only when there was a flame touching the wool.

In a more controlled environment, we also performed this test with an entire Wool Envelope (paper exterior and wool inlay) that had a carton box inside. We found it took 14 seconds for the paper envelope to ignite.

The wool inlay burned only in the parts where it was touching the paper envelope, and the carton box inside the Wool Envelope never caught fire, but it did get some external heat damage.

For comparison, we also put a regular bubble mailer to the same test. The mailer had a paper exterior and bubble wrap interior. It took 6 seconds for the paper mailer to ignite, and both the paper as well as the plastic bubble wrap burned fast, lighting the carton box inside them as well.

Our packaging tests prove Woola packaging to be a durable, water-repellent, temperature-regulating and fire-resistant alternative to plastic bubble wrap. Now you can be sure your fragile products are well-protected when shipped inside a Wool Envelope, while helping reduce the amount of plastic waste in the world.

P.S: Do you want to try out Wool Envelopes for shipping packages safely and sustainably? Request samples today.