Why wool? And why do farmers burn it?

We still can’t wrap our heads around the fact that up to 90% of sheep wool is burned or buried in countries across Europe — that’s around 200,000 tonnes every year. It’s a fact that inspired us to start Woola.

Our ambition to fix the packaging industry goes way back to the pre-Woola times when we were running an ecommerce business. Like most ecommerce companies, we relied on plastic packaging made of fossil fuels.

We invested lots of time and money into trying out different bubble wrap alternatives, but none of them met our expectations. So when we found out about waste wool — a naturally high-tech material that can kick plastic out of the picture — it just made sense to use it.

“Jevgeni and I started looking for an alternative to plastic bubble wrap, and it was really difficult to find one. I saw this newspaper article saying that 90% of wool goes to waste in Estonia. So this instantly clicked for me.”

— Anna-Liisa Palatu, CEO & Co-founder at Woola

We started prototyping and found out that it actually works. This made us very excited about the future.

It all sounded too good to be true… until we faced the first gigantic challenge: there was no proper supply chain for such “low-grade” wool.

So, we set out to build one.

“Through a series of company visits and interviews, we realised that plastic packaging waste is a problem for many companies, and they're not sure how to solve it, and there were no other [sustainable] solutions.”

— Jevgeni Širai, Co-founder at Woola

A win-win supply chain

To save leftover wool from going to waste, infrastructure needs to be set up from scratch.

What would you do if someone took your year’s work, paid you half what it’s worth, and told you they’re doing you a favour with this? Yup, that’s why farmers prefer to compost or burn their wool.

First and foremost, we need to build relationships with sheep farmers and shearers.

From there, the wool needs to be industrially washed, processed and distributed for manufacturing. The key is to set up the whole process in a way that benefits not only us as a company but also sheep farmers, sheep, and everyone else along the way.

“We’ve had to find uses for waste wool all these years, and I think we’ve sold very little of it. Mostly it’s been in compost.”

— Morgan, Sheep farmer

Too many farmers have been outsiders in the wool supply chain for years — because their wool’s quality is not high enough for producing yarn.

There are a few players in the market who buy wool from them, but they offer a very low price, don’t value their product or are just unreliable.

Sheep farmers are looking for a reliable partner, who would value their product, help cover the costs of shearing and help turn the material into something meaningful.

Watch the video below to hear Morgan, a sheep farmer in Rägavere, Estonia, share his story.

Finding the right partners

Going out and actually meeting farmers face to face is key in understanding them. Finding out their real pains and building partnerships on a similar set of values.

We’re very lucky that one of our founders has been in the wool business for over 15 years and is already an insider in the waste wool area.

“I did my doctoral thesis in textile design, and one of the case studies was on wool packaging. Later, Anna-Liisa, Jevgeni, and I met, and that’s when we started Woola.”

— Katrin Kabun, Co-founder & Product Manager at Woola

We’ve set “low standards” for the quality of wool but very high standards for where the wool comes from.

We only work with farms that take good care of their sheep, give them plenty of space, proper feed, and shear them without harming the sheep in any way.

“Our wool would be okay for other uses. I mean, it’s clean and quality wool. It’s sad to compost it.”

— Morgan, Sheep farmer

No to factory farms

To make that extra clear: we don’t work with factory farms. Factory farming is an industry that’s designed to maximise production while minimising costs. Intensive farming uses crops as feed since large-scale farming on scraps isn’t possible.

The industry doesn’t invest in the well-being of sheep because this doesn’t affect their end goal. Factory farms grow sheep in dubious living conditions. The animals lack space and we have little insight into their shearing practices.

They’re also environmentally unsustainable and just don’t make any sense.

There’s a better way

There are farmers who have been herding sheep on their land for decades. We visited many of these farms in Estonia. The sheep live freely on grasslands, some of which have been passed on to the farmers by previous generations.

They farm small flocks, usually under 100 sheep. We looked at how the sheep live and how they’re sheared.

The financial sector has KYC, we have KYW — Know Your Wool. We’re visiting all the farms we gather wool from and make sure they fit our profile for ethical wool.

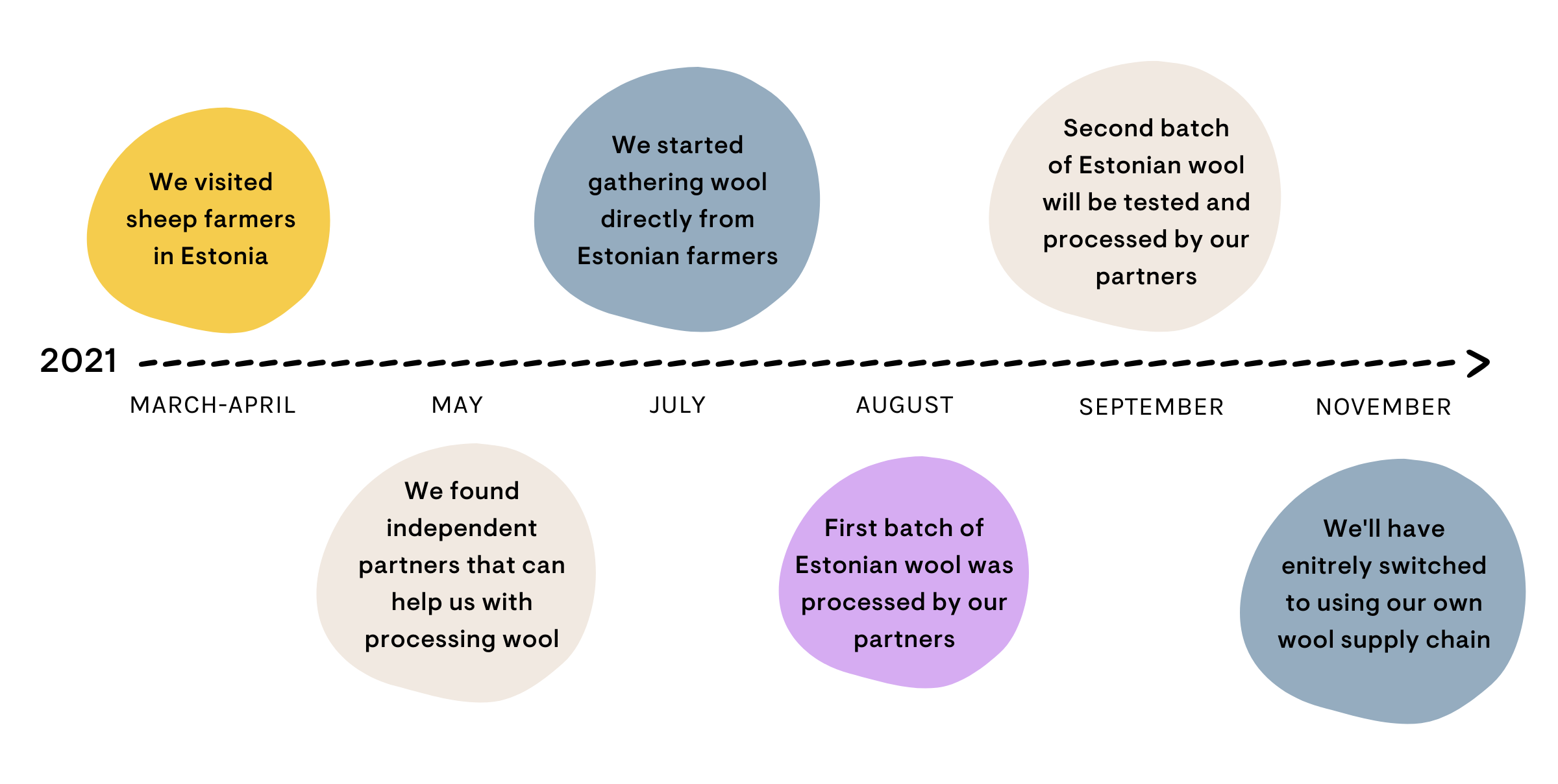

The timeline

We started building the wool supply chain in early 2021, piece by piece. See the initially planned timeline below.

Edit (January 2023): While this timeline turned out to be a little too ambitious, we switched to wool sourced locally in Estonia in 2022.

Our wool product tests

We initially developed three flagship products using waste wool:

Waste wool is processed and pressed in our proprietary process to make Woola packaging. We wanted to test if all the inherent benefits of wool translate to our packaging, so we performed the following product tests:

Is Woola packaging shockproof?

Are Wool Envelopes waterproof?

Does wool protect from temperature extremes?

Is Woola packaging fireproof?

The TL;DR version of our findings: Woola packaging effectively protects products from a 1m drop, is water-repellent (but not waterproof), and temperature- and fire-retardant.

Our Wool Envelopes were sealed with a plant-based binding agent called PLA (polylactic acid) — it was better, but not perfect, as this binding agent relies on cornstarch (a highly genetically modified crop).

We effectively did away with PLA in 2025 and released our more sustainable 100% Wool Envelope inlays.

We’re also currently conducting tests on how long Woola packaging takes to biodegrade in a non-industrial composting environment.

Continuous testing helps us understand how our packaging interacts with nature when it’s disposed of. But we also encourage end customers to return, reuse, or repurpose Woola packaging. All this is in an effort to encourage sustainable, circular packaging practices and get rid of plastic packaging waste for good.

Do you want in on our beef with plastic? Follow us on social media (Facebook, Instagram, and LinkedIn) and subscribe to our newsletter below for future updates (including top sheep content).

Request your free Woola packaging sample here or chat to our sales team.

Frequently asked questions

-

Very few sheep farmers can use or sell the low-grade wool they’re left with after shearing their sheep.

Wool used for yarn must meet strict criteria, which means a lot of good, clean wool doesn’t get used.

Some businesses try to take advantage of this by offering low prices to farmers or simply not paying at all for their low-grade wool. This is why farmers feel it’s better to compost or burn their own wool to return the nutrients to their own land.

-

No, waste wool is a by-product of sheep farming for meat. While meat-eating may be contentious to some, there’s no inherent harm caused to sheep when they’re sheared. In fact, shearing their wool is essential for their health and quality of life.

At Woola, we ensure our local wool partners take good care of their sheep and give them ample space to roam and feed on scraps.

-

Wool has inherent qualities that make it ideal for packaging: it’s durable, shock-proof, water-resistant, and fire-retardant.

Unlike like plastic, wool isn’t harmful to the planet when it’s thrown away or ends up in landfills. It decomposes and feeds the soil with nutrients.